HOW TO CLEAN GROUNDS

Ground connections are very important to the proper operation of electrical and electronic circuits. Grounding concerns can occur on both low and high amperage circuits. Poor grounding such as loose or corroded grounds can drastically affect the circuit, which can result in intermittent or permanent loss of the circuit. Resistance variations caused by poor ground connection or corrosion can adversely affect computer controlled system operation.

GROUND INSPECTION

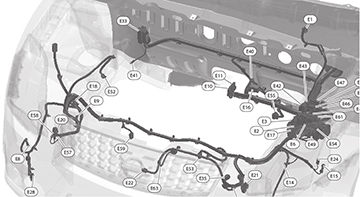

Testing electrical circuits is an easy task if it is approached in a logical and organized method. When troubleshooting an electrical problem the first place to look is these grounding locations. Body ground connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can create an unwanted resistance which can change the way a circuit works.

- Even when the ground connection looks clean on the outer surfaces, there can be a thin film of rust or dirt buildup on the surface between the ground and the body, or on the ground screw or in the mounting hole creating unwanted resistance.

- If there is a intermittent operation condition with an electronic circuit, perhaps the problem is caused by corrosion.

NOTE: Remove the ground bolt or screw from the mounting location, inspect and clean.

There are two basic types of grounding surfaces:

Non-Painted

- Engine

- Transmission

- Plated Metal Brackets

- Non-Plated Metal Brackets

Painted Surfaces

- Vehicle Body

- Painted Metal Brackets

- Part of the Vehicle Body

- Accessory Component Brackets from Supplier

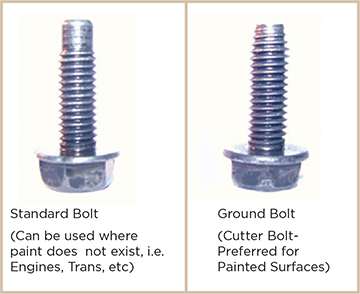

Types of Ground Bolt Fasteners

When inspecting a ground connection observe these rules:

- Nissan uses different types of fasteners to connect body ground harnesses to the vehicle. The type of bolt threads used on the ground bolt fastener depends on the ground connection and the type of mating surface the bolt affixes to.

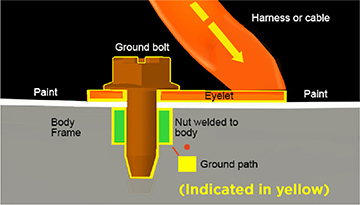

- Bolt and weld nuts welded to the body (most common)

- Stud welded to the body and nut used as a fastener (usually on the under body)

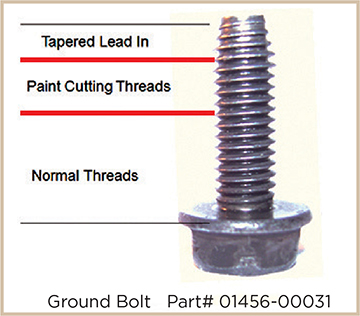

- Some body ground fasteners (ground bolts) are used for burring through paint on the body (common locations are the engine compartment body frame, or at the lower A-Pillar kick panel area)

If a ground connection goes to a painted body surface, the contact between the threads of the ground bolt and mounting hole is the ground path. This makes it imperative that a correct ground bolt is used, in order for there to be good connectivity.

Types of Ground Bolt Fasteners (continued)

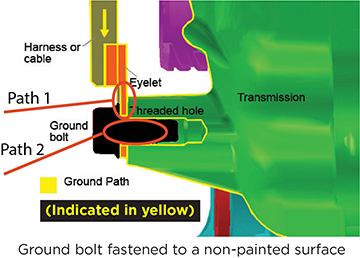

There are two ground paths available when a ground bolt or screw connects to a non-painted surface:

Ground Path 1 - Is the flat machined surface (like the Engine) to the flat surface of the harness ground eyelet.

Ground path 2 - Is the harness ground eyelet to ground bolt head to the bolt threads.

NOTE: If the ground bolt condition is questionable, replace the bolt with a new ground bolt that is specified for use at that location.

Ground bolt fasteners for a painted surface

Ground bolts used to ground a harness to a painted surface are hard to identify from another bolt.

However they are different, that’s because they are designed with special threads that help ensure they cut through the paint to help make good metal to metal contact.

NOTE: Nissan uses three common ground bolt fasteners. Use the FAST system to order the applicable ground bolt:

- Part# 01456-00411

- Part# 01456-00031

- Part# 01456-N8011

Performing a visual inspection is the first step to determining if there’s a good ground when a ground harness is connected to a painted surface. To do this properly it’s imperative that you disconnect the ground fastener connector to:

- Inspect all mating surfaces for tarnish, dirt, rust, etc.

- Clean as required to assure good contact:

- Remove any rust from the bolt (screw) or replace the bolt, ground connector.

NOTE: Clean all surfaces with a wire brush.

- If necessary, use a tap with correct size and thread pitch to clean the mounting hole threads.

IMPORTANT NOTE:

Do notremove the paint from the mounting point, as that may allow rust or corrosion to occur.

Removing the paint from the body frame at the ground bolt mounting area in the attempt to create a better ground connectivity may help in the short term, but, doing this may allow a corrosion condition to occur overtime.

- Reinstall bolt or screw and torque securely.

NOTE: Performing a voltage drop test after cleaning or replacing ground bolt helps you to determine a good ground connection which helps ensure proper operation of electrical and electronic circuits.