The QX30 uses a Dual Clutch Transmission (7DCT), which simply put, is a manual transmission gearbox complete with idler gears, synchronizers, and shift forks that is operated automatically. The dual clutch acts as an interface between the engine and transaxle and allows uninterrupted torque transfer during shift operations. The dual clutch transmission has seven forward gears and one reverse gear. Both clutch operation and gear changes take place on a fully automatic basis. A TCM controls the shift forks using two control valve solenoids and hydraulic pressure. A major component to this DCT is the dual clutch which is the subject of this article.

Some of the advantages of the dual clutch transmission are:

- Faster shifting

- Increased fuel economy

- Ability to handle higher torque values

- Suitability for use with the Idle Stop/Start system

- Smaller transaxle housing

- Short shift times

- Very smooth shifts

DUAL CLUTCH ASSEMBLY FUNCTION AND OPERATION

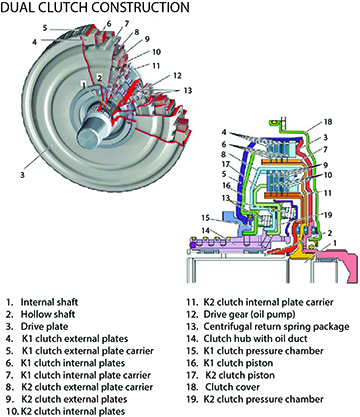

The DCT uses a clutch assembly that contains two multi-disc clutches which are alternately electro-hydraulically actuated to engage or disengage. Each multi-disc clutch is coupled to a sub-transmission. The dual clutches function similarly to automatic transmission clutch packs, but look more like a torque converter.

NOTE: The DCT is not equipped with a torque converter.

The input shaft is comprised of an internal shaft and an outer hollow shaft. The K1 clutch is coupled to the internal solid shaft and the K2 clutch is coupled to the hollow shaft. The K1 clutch (outer multi-disc clutch) engages the odd forward gears 1, 3, 5, and 7, and the K2 clutch (inner multidisc clutch) engages the even forward gears 2, 4, 6 and the Reverse gear. In order to transfer the drive torque of the engine to the internal or hollow shaft and then onto the respective sub-transaxle, one of the clutch packs first has to be frictionally connected via the application of hydraulic pressure. Torque transfer takes place on an alternating basis via K1 clutch (outer multi-disc clutch) and K2 clutch (inner multi-disc clutch).

With the ignition ON and the shift selector in Neutral, both clutches are open. The drive shafts are at a standstill and no torque is transmitted into the transmission.

However, both Gear 1 and Reverse are pre-selected in anticipation of driver requirements. The gear expected to be engaged next is pre-selected by the transmission control unit (but when the associated clutch is still open there is no torque transmission).

During driving operation (with the exception of Reverse gear), only one gear of a sub-transmission is ever transmitting power at one time.

As driving operation proceeds:

- Torque is transferred from the engine’s crankshaft to the drive plate and onto the internal input shaft or hollow input shaft on an alternating basis depending on whether the K1 clutch or K2 clutch is engaged.

- Power flow takes place via the corresponding internal or hollow shaft fixed gear to the associated output shaft idler gears, depending on which clutch is engaged.

Torque transfer takes place when the idler gear and the associated fixed gear are moved into connection of their toothed profiles when either the K1 clutch or K2 clutch is alternately frictionally connected via the application of hydraulic pressure.

As the engine, transmission and road speed/load increase, so does the transmission oil clamping force required to hydraulically stop the multi-disc clutch plates from slipping.

The electro-hydraulic pressure is controlled by the TCM via two control valves:

- K1 clutch regulation valve

- K2 clutch regulation valve

POWER FLOW THROUGH THE DUAL CLUTCH

Engine torque output flows to the DCT through the crankshaft drive plate. When the K1 clutch engages, power flows through the solid input shaft and through the output shaft 1 or 2 depending on the gear selected. If the K2 clutch engages, torque flows through the hollow shaft and through the output shaft 1 or 2 to the pinion differential depending on the gear selected.

The blue color in the illustration shows how K1 works with the solid inner input shaft, and the green color in the illustration shows how K2 works with the hollow input shaft.

Was this article helpful? We value your opinion! Email us at TechTalk@nissan-usa.com.