2017 VQ35DD DIRECT INJECTION GASOLINE™ (DIG)

The Direct Injection Gasoline™ (DIG) system helps the engine achieve better:

- Wide-Open-Throttle (WOT) performance

- Fuel economy

- Emissions performance

The DIG system allows more accurate adjustment of the fuel injection quantity by injecting atomized high-pressure fuel directly into the combustion chamber of each cylinder rather than into the intake port.

With the DIG system:

- A higher compression ratio is possible, which results in increased power output.

- Reduced time is needed for the fuel to burn.

- There is less residual fuel buildup.

- More efficient combustion means cleaner exhaust.

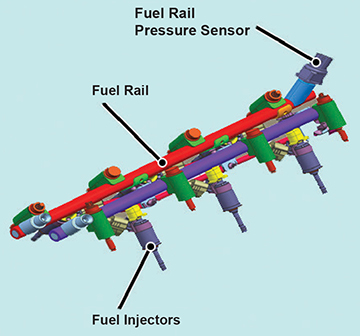

The main components of this system are the:

- High-pressure fuel pump

- High-pressure fuel pump control solenoid valve

- High-pressure fuel lines

- Fuel rail pressure sensor

- High-pressure fuel injectors

Precaution for the High-Pressure Fuel System

- The high-pressure fuel system components are located between the high-pressure fuel pump and the fuel injector.

- Always release the fuel pressure and never start the engine when performing removal and installation of these components.

- When removing or installing parts without releasing fuel pressure, fuel may be splashed and, if fuel contacts skin or eyes, it may cause inflammation.

![]()

Before disconnecting any high-pressure line, be sure to release the fuel pressure from the lines. The high-pressure fuel system operates at extremely high pressures. Fuel in the high-pressure pump supply lines, fuel rails, and fuel injectors reach pressures over 2,800 psi. For this reason, extreme caution should be used when working around the fuel system.

The fuel pressure release procedure should be followed anytime fuel system components are removed or fuel lines are loosened. Fuel pressure release can be performed using CONSULT by accessing Active Test and selecting FUEL PRESSURE RELEASE. Without CONSULT, fuel pressure can be released by removing the fuel pump fuse and then running the engine until it stalls. After the engine stalls, crank the engine several additional times to release any remaining fuel pressure.

IMPORTANT NOTE:

Place pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pressure cannot be completely released because this model does not have a fuel return system.

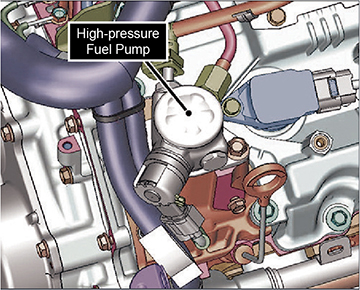

High-Pressure Fuel Pump

The high-pressure fuel pump is driven by the left exhaust camshaft. It compresses the fuel and then delivers high-pressure fuel to the fuel injectors via the fuel rails.

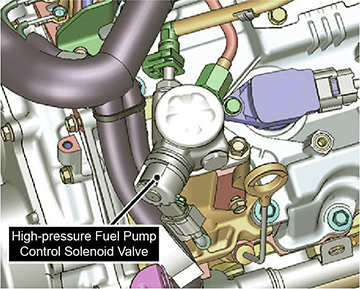

High-Pressure Fuel Pump Control Solenoid Valve

The ECM controls the high-pressure fuel pump control solenoid valve, built into the high-pressure fuel pump, to adjust the amount of fuel discharge. The solenoid is replaced as a unit with the high-pressure fuel pump.

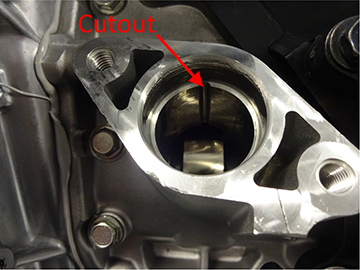

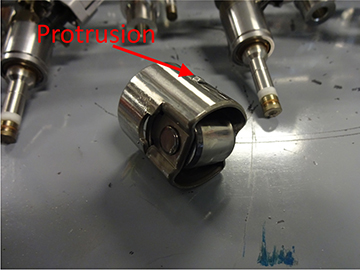

NOTE: Before installing the high-pressure fuel pump, be sure that the exhaust camshaft fuel pump lobe is at bottom dead center and the cutout is in line with the protrusion on the lifter.

High-Pressure Fuel Pump Control Solenoid Valve

The high-pressure fuel pump control solenoid valve is located on the inlet side of the high-pressure fuel pump and is controlled by the ECM. Low-pressure fuel is delivered to the high-pressure fuel pump control solenoid valve by the in-tank fuel pump. The ECM adjusts the quantity of fuel that enters the high-pressure pump by pulse-width modulating the high-pressure fuel pump control solenoid valve.

High-Pressure Fuel Feed Tube

The fuel feed tube runs from the high-pressure fuel pump to the fuel rail.

![]()

Do not reuse fuel feed tube to help prevent against fuel leaks.

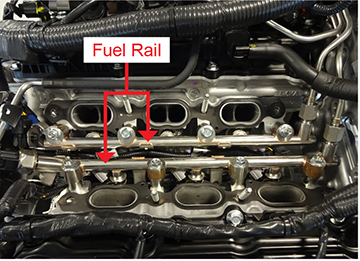

Fuel Rail

The high-pressure fuel system uses one fuel rail for each bank of fuel injectors. The fuel rail runs under the intake manifold. The fuel rails store high-pressure fuel from the high-pressure fuel pump for delivery to the fuel injectors. Remove the intake to access the rail.

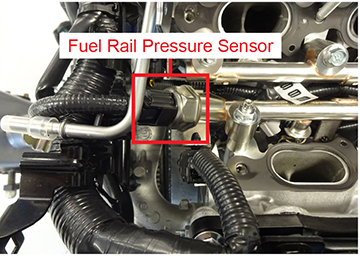

Fuel Rail Pressure Sensor

The fuel rail pressure sensor transmits a voltage signal to the ECM. As the pressure increases, the voltage rises. The fuel rail pressure sensor monitors the amount of fuel pressure in the fuel rails and provides feedback to the ECM. The ECM uses this information to vary the duty cycle and operate the high-pressure fuel pump and control the fuel pressure.

![]()

- Do not reuse fuel rail pressure sensor.

- Do not use a fuel pressure sensor that has been dropped.

Fuel Injectors

Three high-pressure fuel injectors are mounted on each fuel rail. The fuel injectors are high-pressure and high voltage, which allows more precise adjustment of fuel delivery into each combustion chamber. The ECM uses an injector driver to actuate the fuel injectors at voltages as high as 65 V.

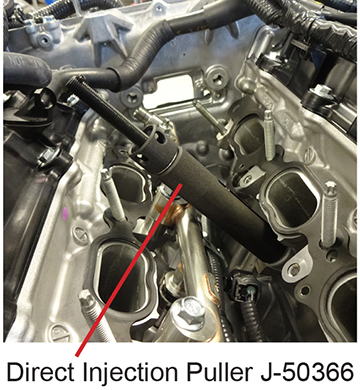

NOTE: If the fuel injector needs to be removed, whether the cylinder head is installed or removed, use the Direct Injection Puller J-50366. This special tool overcomes any resistance caused by carbon buildup during injector removal.

![]()

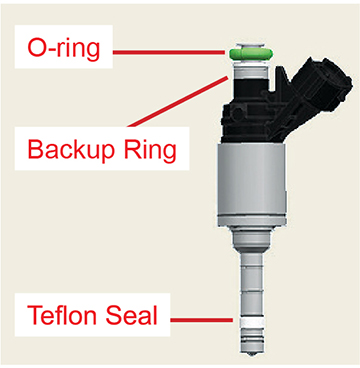

- Do not reuse seal ring.

- Do not reuse fuel injector holder, O-ring (green) and backup ring.

![]()

The fuel pressure release procedure should be followed anytime fuel system components are removed or fuel lines are loosened. Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger of fuel spray or leaking.

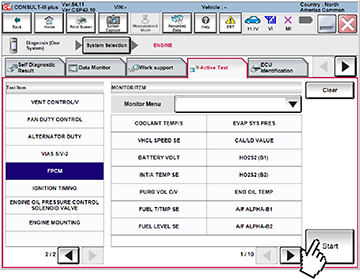

Fuel Pressure Release with CONSULT-III Plus

1. Turn ignition switch ON.

2. On CONSULT-III plus screen, select “ENGINE” >> “Active Test” >> “FPCM” >> “Start”.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Fuel Pressure Release Without CONSULT-III Plus

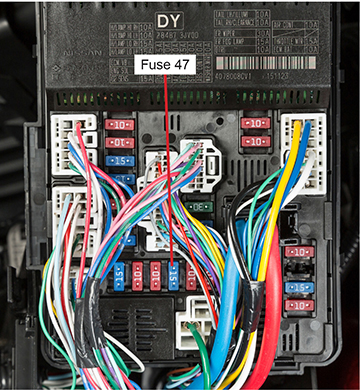

1. Pull out 15A fuse (No. 47) from IPDM E/R.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.